Needle rollers, characterized by their small cylindrical shape with lengths several times greater than their diameters, are essential components in radial needle roller bearings.

These bearings are designed specifically to handle radial loads, boasting compact radial dimensions compared to bearings of similar hole diameters. This compactness renders them ideal for machinery with restricted radial space. However, their ability to tolerate angular shaft misalignments relative to the housing is limited.

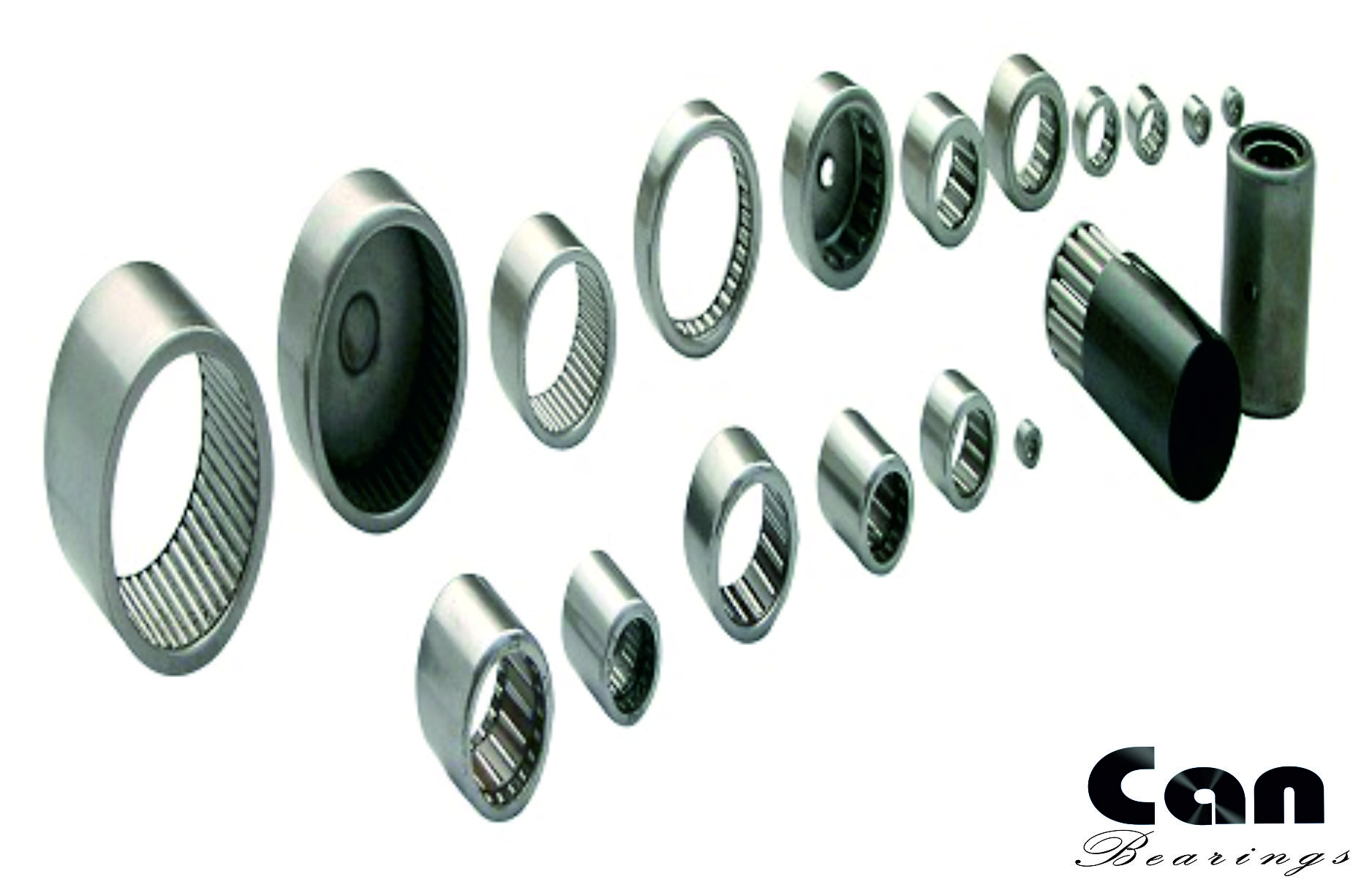

Radial needle roller bearings are available in a wide array of designs, including those featuring pressed outer rings, rings made of bearing steel, or cages with rollers but no rings. They typically comprise one or two rows of rolling elements and can be either open or equipped with protective contact seals.

Manufactured with pressed steel or glass fiber-reinforced polyamide cages, radial needle roller bearings can also be produced without cages, allowing for the maximum number of rollers to achieve very high radial load capacity.